About GRP Panel Tanks

Why Choose GRP Tanks

Resistance to corrosion

In contrast to steel, GRP (Glass Reinforced Plastic) exhibits complete resistance to corrosion. In instances where metal components are necessary, our GRP tanks incorporate top-tier stainless steel, known for its exceptional resistance to corrosion. This ensures a dependable and secure water supply, eliminating the necessity for continuous maintenance.This feature ensures the longevity of the tank by preventing rust or degradation over time.

Durability

Tanks are known for their robust and durable construction, ensuring they withstand harsh environmental conditions and maintain structural integrity over an extended period.The durability of a water tank is often determined by the strength and resilience of the materials used in its construction. Tanks made from high-quality materials such as polyethylene, fiberglass, or steel are known for their robustness.

Lightweight Design

Compared to traditional materials like steel, GRP tanks are considerably lighter. This feature simplifies transportation, installation, and handling, making them a practical choice for various applications.Water tanks with a lightweight design offer practical advantages during transportation, handling, and installation.The reduced weight simplifies logistics, making it easier to transport the tank to the installation site.

Excellent Heat Insulation

Water Tank Facility

Certificate/Test Report

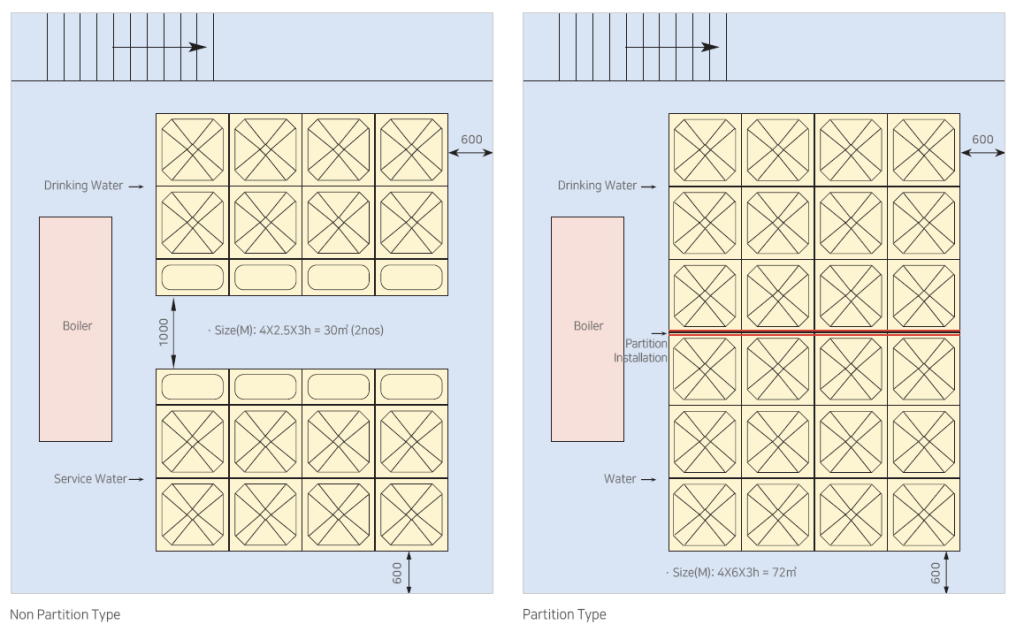

1. Special feature

- Utilizing maximum capacity

- – In the basement or other confined areas, it is possible to eliminate unusable space,and utilize the maximum space, by installing apartition type tank.

- Various uses

- – If partition type tanks are installed, one section can be used for drinkin gwater, and the other section for service water(Ex.fire fighting).

- Easy Maintenance

- – It is convenient for maintenance, because two tanks can be installed as one unit.

- Cost effectiveness

- – The cost and installation of 1 partition tank is cheaper than 2 separates tanks.

2. Partition Installation

3. Effect for Partition Water Tank System

– If tanks for two different uses are needed in a confined area or boiler room, a 72㎥ partition type tank can be installed to use half for drinking water, and half for service water. If separate tanks are installed, however, you have to installed two tanks with a maximum of 30㎥, because you need to have 1 meter distance between tanks for maintenance and operating space.

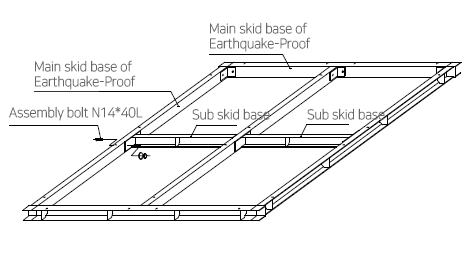

4. Earthquake-Proof Skid Base System

– Height of water tank 2.5m.H, Height of water tank 4m, GRP sectional Panel, Putting water to 85% of water tank height, Earthquake-Proof Strength 5.0Result of testing base frame (Safety 2.0)

| Height | Contents | Bending Stress(kg/c㎡) | Drooping((cm) | |

|---|---|---|---|---|

| 2.5mH | Main | Long | 1170 < 1600(Allowable value) ■ O.K | 0.15 < 0.25(Allowable value) ■ O.K |

| Skid | term | |||

| Base | Short | 1340 < 2400(Allowable value) ■ O.K | 0.17 < 0.33(Allowable value) ■ O.K | |

| term | ||||

| Sub | Long | 1590 < 1600(Allowable value) ■ O.K | 0.21 < 0.25(Allowable value) ■ O.K | |

| Skid | term | |||

| Base | Short | 1830 < 2400(Allowable value) ■ O.K | 0.25 < 0.33(Allowable value) ■ O.K | |

| term | ||||

| 4mH | Main | Long | 790 < 1600(Allowable value) ■ O.K | 0.06 < 0.25(Allowable value) ■ O.K |

| Skid | term | |||

| Base | Short | 900 < 2400(Allowable value) ■ O.K | 0.27 < 0.33(Allowable value) ■ O.K | |

| term | ||||

| Sub | Long | 1540 < 1600(Allowable value) ■ O.K | 0.15 < 0.25(Allowable value) ■ O.K | |

| Skid | term | |||

| Base | Short | 1750 < 2400(Allowable value) ■ O.K | 0.17 < 0.33(Allowable value) ■ O.K | |

| term | ||||

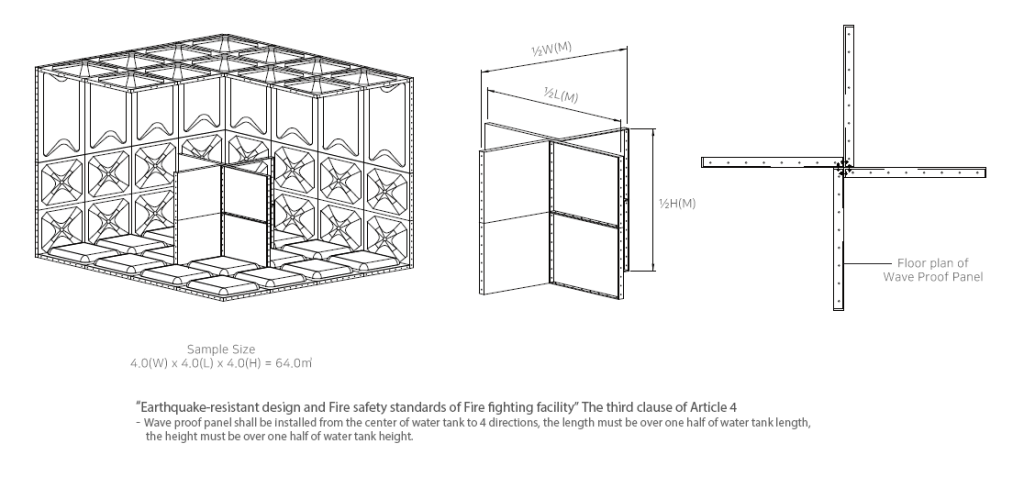

5.Wave Proof Panel for Earthquake-Proof

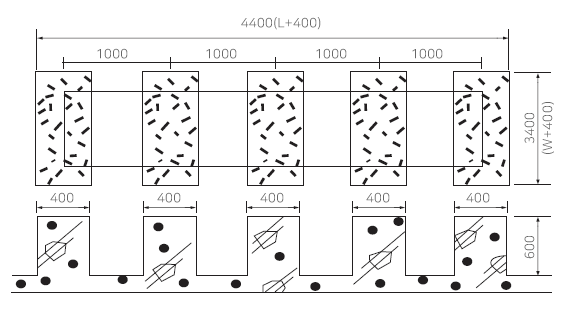

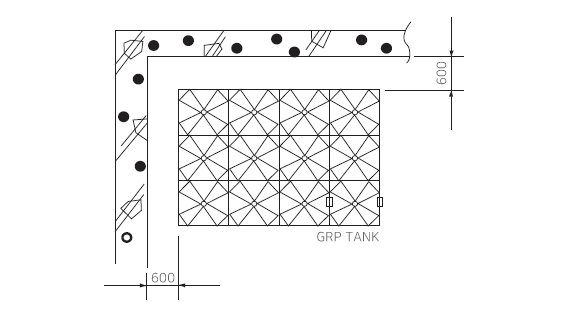

6.Installation Standard(Pad and Space)

Result of Skid base strength review(Safety Factor 2.0)

Standard of Base Concrete PAD Installation and Space – For maintenance of GRP tank, it needs extra space at least 600mm from wall and 1,000mm from ceiling.

Your Trusted Ariston Solar Water Heater Supplier: Reem

As the leading provider of Ariston products in the UAE, Reem stands out as your one-stop destination for all your heating needs. Whether you’re looking for sellers, suppliers, or distributors of Ariston products, Reem has you covered with an extensive range of high-quality options. With our commitment to excellence and customer satisfaction, we ensure that you have access to the best Ariston products available in the market. Trust Reem to be your reliable partner in fulfilling your heating requirements across the UAE.