GRP Panel TANKS

About GRP Panel Tanks

Why Choose GRP Tanks

Resistance to corrosion

In contrast to steel, GRP (Glass Reinforced Plastic) exhibits complete resistance to corrosion. In instances where metal components are necessary, our GRP tanks incorporate top-tier stainless steel, known for its exceptional resistance to corrosion. This ensures a dependable and secure water supply, eliminating the necessity for continuous maintenance.This feature ensures the longevity of the tank by preventing rust or degradation over time.

Durability

Tanks are known for their robust and durable construction, ensuring they withstand harsh environmental conditions and maintain structural integrity over an extended period.The durability of a water tank is often determined by the strength and resilience of the materials used in its construction. Tanks made from high-quality materials such as polyethylene, fiberglass, or steel are known for their robustness.

Lightweight Design

Compared to traditional materials like steel, GRP tanks are considerably lighter. This feature simplifies transportation, installation, and handling, making them a practical choice for various applications.Water tanks with a lightweight design offer practical advantages during transportation, handling, and installation.The reduced weight simplifies logistics, making it easier to transport the tank to the installation site.

Water Tank Panel

Watertightness, Drain Capability and Strength of Water Tank

Reinforcement Structure

Partition Type Water Tank

Excellent Heat Insulation

Water Tank Facility

Certificate/Test Report

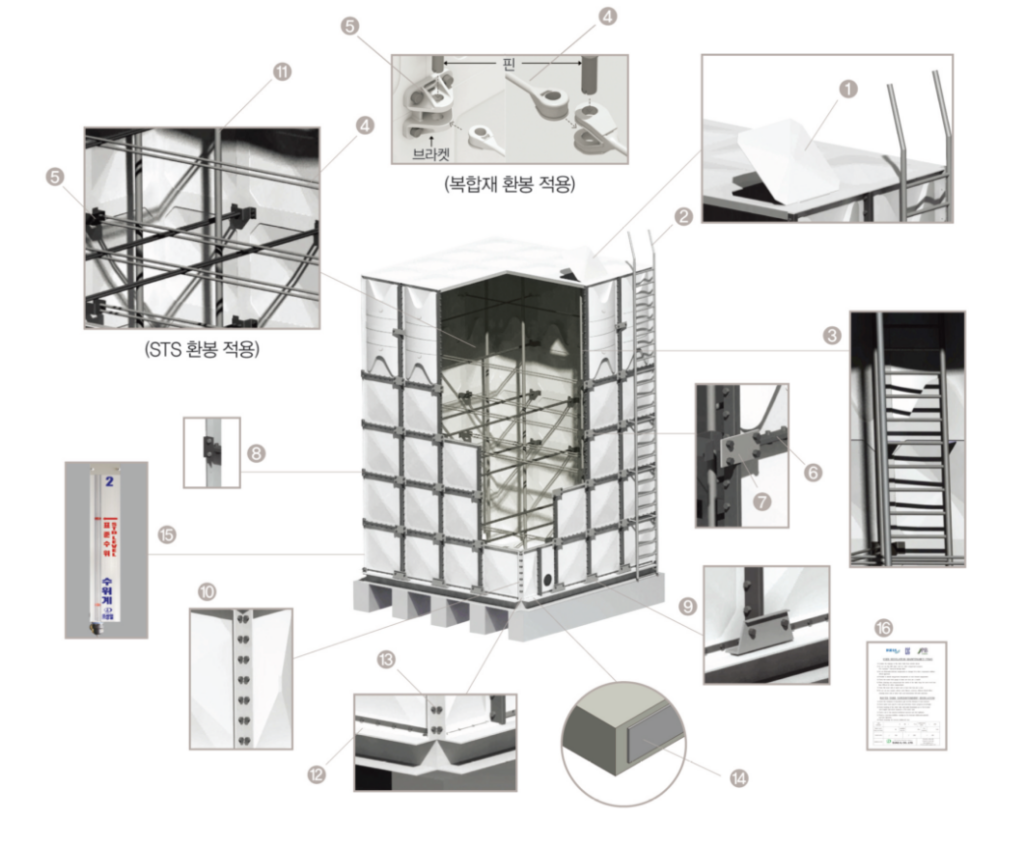

1. Inner Reinforced GRP Water Tank

Internally Reinforced System

- – It is possible that various capacity’s design and flexible space should be used by GRP panels standardized

- – Excellent water tightness, hygienic conditions and non-leakage applied internally reinforced stay(Stainless)

| NO . | Name | Material | NO . | Name | Material |

|---|---|---|---|---|---|

| 1 | Manhole Panel | GRP | 11 | Roof Support Pipe | GRP ( Pultrusion ) |

| 2 | External Ladder | SS400 ( HDG ) | 12 | Base Frame | SS400 ( HDG ) |

| 3 | Internal Ladder | GRP | 13 | Bolts and Nuts | Inside STS : Bolt / Nut ( 304 , 316 ) , Washer ( 316 ) |

| 4 | Internal Tie Rod | STS ( PET Coating ) , STS 304 , 316 | Roof Panel : acetyl cap bolt ( M10 ) | ||

| 5 | Internal Bracket | STS ( Epoxy Coating ) , STS 304 , 316 | Outside : HDG Bolt + PVC Bolt cap | ||

| 6 | Flange Bar , Flat Bar | SS400 ( HDG ) | Connection : HDG + Acetyl Cap ( M14 ) | ||

| 7 | External Bracket . | Size : M10 , M14 | |||

| 8 | Corner Bracket | 14 | Sealing Tape | PVC Sealant + Butyl or EVA Sealant + PVC Sealant | |

| 9 | Bottom Bracket | 15 | Water Level Gauge | Aluminum Case + PE Clear Tube + Socket | |

| 10 | Corner Frame | 16 | Name Plate | Aluminum ( Water Tank Safety Management Instructions ) |

Strength & Durability of GRP Water Tank

| Section | Design Standard |

| Hydrostatic Pressure | Water pressure reinforcement 4 times standard Transformation rate in filled u with water: Less than 1% form water tank heigh |

| Wind Force | Less than 60m/sec |

| Earthquake Force | Stable and safe till magnitude 5.0 (Over magnitude 5.0, it needs additional reinforcement) |

| Snow load | 60Kg/㎡, , Snow fall less than 30cm |

| Illumination Rate | Less than 0.1% |

| Out-fitForce | No leakage under condition of vertical 100Kg after install of 100A fitting with 70mm span supprot |

| Water Temperature | Usable temperature: Less than 30℃, Limited temperature: Max 70℃ |

| Water quality | Tap water, well water: chlorine below 50mg/ℓ Seawater: applicantion Externally Reinforced water tank(max 3m height) |

Features of Internally Reinforced System

- Excellent Hygienic Conditions

- – Internal tie-rod of water tank is coated with PE and internal bracket is coated with powder.

- – Internal Bolt for tie-rod and bracket is coated with epoxy after fastening.

- – Prevented rust appearance as Chlorine GAS stay through external assembly bolts(HDG) added PVC bolt-caps of water tank.

- Outstanding View

- – Prevented white peril or rust appearance through external assembly bolts added bolt-capsofWaterTank, and outstanding view.

- Easy to Assembly

- – Easy to assembly through internal and external optimized options of reinforced system.

- Best Structure Stability

- – SUNGIL CO., LTD’s internally Reinforced System is verified structure stability of water tanks which have built in domestic and international sites for 20years.

2. External Reinforced GRP Water Tank

Externally Reinforced System

By using external reinforcement bar at the exterior, it is minimizing internal reinforcement bar. Strengthened GRP water tank system is to simplify construction and reinforce cleanliness.

| NO | Name | Material | NO | Name | Material |

|---|---|---|---|---|---|

| 1 | Manhole Panel | GRP | 10 | Base Frame | SS400 ( HDG ) |

| 2 | External Ladder | SS400 ( HDG ) | Inside STS : Bolt / Nut ( 304 , 316 ) , Washer ( 316 ) | ||

| 3 | Internal Ladder | GRP | Roof Panel : acetyl cap bolt ( M10 ) | ||

| 4 | Internal Bracket | STS ( Powder coating ) , STS304 , 316 | 11 | Bolts and Nuts | Outside : HDG Bolt + PVC Bolt cap |

| 5 | External Support Tie - rod | SS400 + Urethane Coating | Connection : HDG + Acetyl Cap ( M14 ) | ||

| 6 | External Pair Frame | Size : M10 , 14 | |||

| 7 | Corner Bracket | SS400 ( HDG ) | 12 | Sealing Tape | PVC Sealant + Butyl or EVA Sealant + PVC Sealant |

| 8 | Corner Frame | 13 | Water Level Gauge | Aluminum Case + PE Clear Tube + Socket | |

| 9 | Roof support pipe | GRP ( Pultrusion ) | 14 | Name Plate | Aluminum ( Water Tank Safety Management Instructions ) |

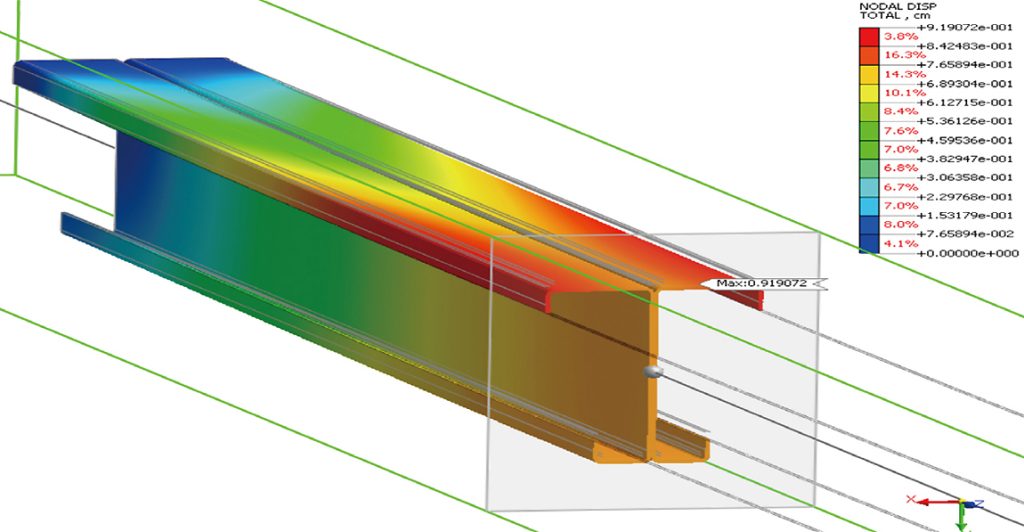

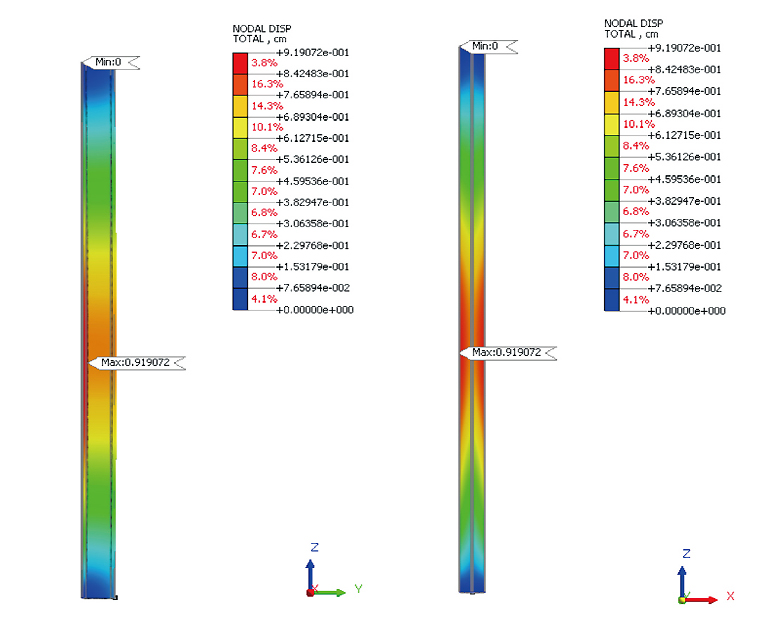

Externally Reinforced System Structural Analysis

FEM – Water Tank Height (3MH-75m)

FEM – External Pair Frame (3MH-75m)

Result of Skid base strength review (Safety Factor 2.0)

| Height | Contents | Bending Stress(kg/㎠) | Result | Remark | |

|---|---|---|---|---|---|

| 3.0mH | Main Skid Base | Long term | 1520 < 1600(Allowed value) | OK | |

| Short term | 2130 < 2400(Allowed value) | OK | |||