GRP Panel TANKS

About GRP Panel Tanks

Reem Group is the leading control panel supplier, offering tailored solutions for diverse industrial needs. A GRP panel, or Glass Reinforced Plastic panel, is a composite material made from a combination of glass fibers and a polymer resin, usually polyester or epoxy. This combination results in a strong and lightweight material that is commonly used in various industries for a wide range of applications.

GRP panels, composed of a polymer resin matrix reinforced with glass fibers, boast a high strength-to-weight ratio and exceptional corrosion resistance. Widely used in construction, transportation, and industrial applications, their manufacturing involves layering glass fibers in a mold, applying resin, and curing through heat and pressure, resulting in a durable material requiring minimal maintenance. However, cost considerations and vulnerability to extreme heat or fire are potential limitations.

Why Choose GRP Tanks

Resistance to corrosion

In contrast to steel, GRP (Glass Reinforced Plastic) exhibits complete resistance to corrosion. In instances where metal components are necessary, our GRP tanks incorporate top-tier stainless steel, known for its exceptional resistance to corrosion. This ensures a dependable and secure water supply, eliminating the necessity for continuous maintenance.This feature ensures the longevity of the tank by preventing rust or degradation over time.

Durability

Tanks are known for their robust and durable construction, ensuring they withstand harsh environmental conditions and maintain structural integrity over an extended period.The durability of a water tank is often determined by the strength and resilience of the materials used in its construction. Tanks made from high-quality materials such as polyethylene, fiberglass, or steel are known for their robustness.

Lightweight Design

Compared to traditional materials like steel, GRP tanks are considerably lighter. This feature simplifies transportation, installation, and handling, making them a practical choice for various applications.Water tanks with a lightweight design offer practical advantages during transportation, handling, and installation.The reduced weight simplifies logistics, making it easier to transport the tank to the installation site.

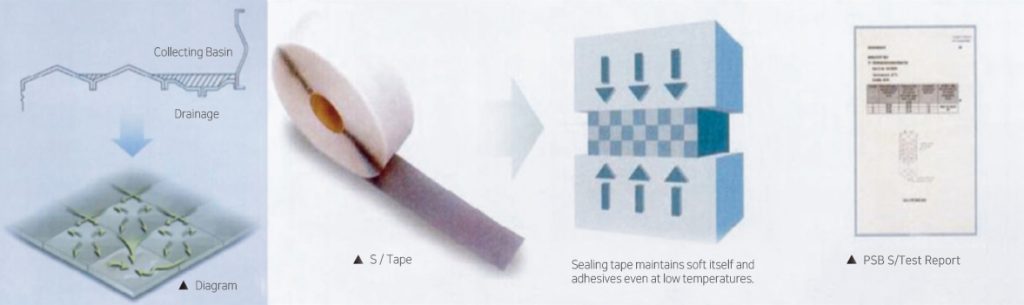

1. Perfect watertight & Drain System

– As using foaming type sealant tape which is excellent water proof & force of restitution, maintains perfect non-leakage of the Water tank. The concave drain panel facilitates complete and quick drainage.

| Type of Sealing Tape | Characteristic | |

| Optional Items | EVA+PVC | Applicable to 50℃ |

| Butyl+PVC | Preventing to Stick PVC | |

| tape out from GRP Panel | ||

2. Strength & Durability of GRP Water Tank

| Section | Design Standard |

| Hydrostatic Pressure | Water pressure reinforcement 4 times standard |

| Transformation rate in filled u with water: Less than 1% form water tank heigh | |

| Wind Force | Less than 60m/sec |

| Earthquake Force | Stable and safe till magnitude 5.0 (Over magnitude 5.0, it needs additional reinforcement) |

| Snow load | 60Kg/㎡, , Snow fall less than 30cm |

| Illumination Rate | Less than 0.1% |

| Out-fitForce | No leakage under condition of vertical 100Kg after install of 100A fitting with 70mm span supprot |

| Water Temperature | Usable temperature: Less than 30℃, Limited temperature: Max 70℃ |

| Water quality | Tap water, well water: chlorine below 50mg/ℓ |

| Seawater: applicantion Externally Reinforced water tank(max 3m height) |